This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Archives: Methodology

Methodology

ACR Validation and Verification Standard

ACR requires independent third-party validation and verification of all GHG projects following the ACR Validation and Verification Standard, which details ACR’s third-party validation and verification requirements that every GHG project must undergo in order for ACR to register GHG emission reductions and removals as carbon credits.

Read more

ACR is developing an updated version 2.0 of the ACR Validation and Verification Standard to align with the most recent versions of the ACR Standard and ISO standards and to provide greater clarity to ACR Validation and Verification Bodies (VVBs) and project developers. A public comment draft is expected to be released in August of 2023. In addition to the ACR Validation and Verification Standard, VVBs should refer to the ACR webpage for Validation and Verification for forms, templates and general information on the process.

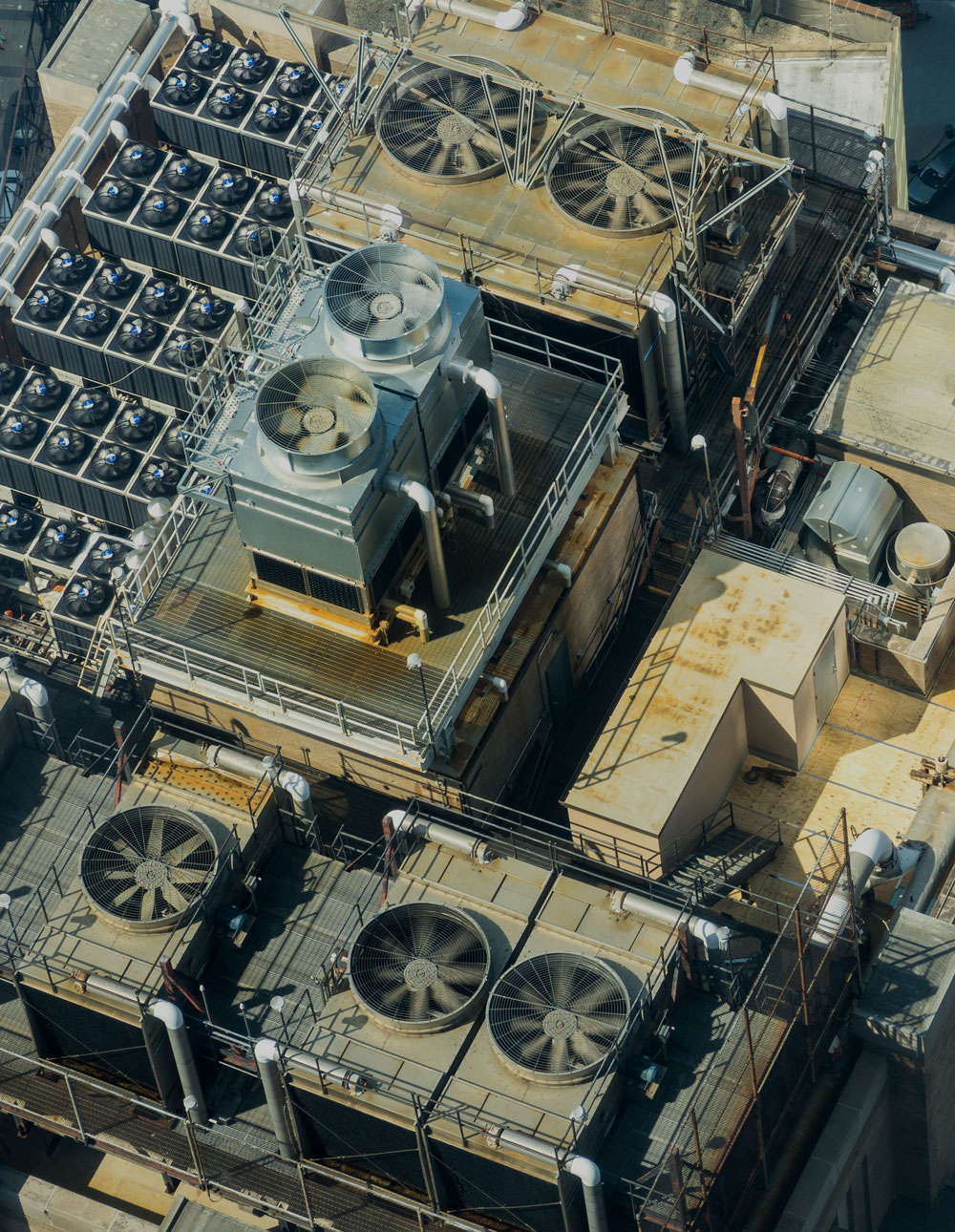

Advanced Heating, Ventilation and Air Conditioning (HVAC) Systems

ACR, a nonprofit enterprise of Winrock International, is developing Methodology for the Quantification, Monitoring, Reporting, and Verification of Greenhouse Gas (GHG) Emissions Reductions from Advanced Heating, Ventilation and Air Conditioning (HVAC) Systems, Version 1.0. This Methodology is being co-developed by ACR & Therm Solutions, Inc.

Read more

The intent of the methodology is to incentivize GHG emissions reductions through the deployment and use of refrigerants with low global warming potential (GWP) in HVAC applications in both residential and commercial settings. Intended eligible equipment categories include: unitary air conditioners, chillers, heat pumps, packaged terminal air conditioners (PTAC), and window air conditioning units.

ACR’s methodology will allow the eligible equipment types within the HVAC market to generate carbon credits when they switch from high GWP refrigerants to lower GWP refrigerants (below 750 GWP) that have been approved under the EPA’s Significant New Alternatives Policy (SNAP) Program. The recovered high-GWP HFC refrigerants may be destroyed to generate additional carbon credits using ACR’s Methodology for the Quantification, Monitoring, Reporting and Verification of Greenhouse Gas Emissions Reductions and Removals from Destruction of Ozone Depleting Substances and High GWP Foam. Greenfield projects where property or business owners choose to install HVACs with low GWP refrigerants will also be eligible to utilize this methodology.

The methodology is based on a robust data set, including published data from the EPA, the 2006 International Panel on Climate Change (IPCC) Guidelines for GHG Inventories, and additionally an industry survey conducted by Therm.

INACTIVE: Plugging Orphaned Oil and Gas Wells

Effective May 9, 2025, ACR has made its Plugging Orphaned Oil and Gas Wells Methodology (version 1.0) (“OOG Methodology”) inactive to update requirements to ensure consistent and appropriate application across diverse project sites and wells and to avoid delays in verification.

Read more

The OOG methodology update does not impact projects that have already been verified or credits that have already been issued. In addition, projects that have approved Methane Measurement Method Approval Forms (MMMAFs) may complete the verification process under version 1.0 of the OOG Methodology.

ACR will work with trusted partners and industry experts to update the OOG Methodology to version 2.0 following ACR’s methodology update process, which includes a public comment period and scientific peer review. Publication of an updated version is planned for 2026.

ACR will continue to accept new project listings until publication of the updated version. New projects, as well as currently listed projects that do not have an approved MMMAF, must be validated and verified for conformance with the updated version 2.0 of the OOG Methodology.

When published in May 2023, the OOG Methodology was the world’s first focused on plugging orphaned oil and gas (OOG) wells in the United States and Canada. In the U.S. alone, the Environmental Protection Agency estimates methane emissions from abandoned wells (of which orphaned wells are a subset) to be at least 7 million metric tons of CO2 equivalent annually, which is likely an underestimate. Over 120,000 orphaned wells have been documented across 30 states in the U.S., and estimates of additional undocumented orphaned wells range as high as several million across the country.

The OOG Methodology is a high priority for ACR given the number of OOG wells, their negative social and environmental impacts, and the woefully inadequate funding available to plug them. The OOG Methodology has already delivered significant carbon market finance to address the crisis and meaningful climate impact through the reduction of methane emissions. The collective experience from over two years of project development, implementation, validation, verification, and credit issuance across a broad OOG landscape provides valuable insights to ensure the OOG Methodology can be scaled to realize its full potential and ongoing climate impact.

INACTIVE: Recycling of Transformer Oil

The ACR methodology for Reduction in Emissions from the Recycling of Transformer Oil is inactive and ineligible for crediting projects on ACR. ACR has determined that the methodology requires updates to be consistent with the current version of the ACR Standard.

Read more

The methodology was developed by Hydrodec Group PLC. The methodology quantifies emission reductions achieved in the U.S. by diverting used transformer oil, which under normal conditions would be incinerated at the end of its useful life, to a refining facility that processes the transformer oil for re-use. Project Proponents achieve emissions reductions by recycling the highly refined oil used in transformers that are operated by electric utility customers and large industrial companies. As a co-benefit, recycling of transformer oil in controlled and permitted facilities reduces the environmental health and safety risks associated with the destruction of Polychlorinated Biphenyls (PCBs) found in transformer oil.

INACTIVE: Re-refining Used Lubricating Oils

The ACR Methodology for the Quantification, Monitoring, Reporting and Verification of Greenhouse Gas Emissions Reductions and Removals from Re-Refining Used Lubricating Oils is inactive and ineligible for crediting projects on ACR. The methodology relies on a performance standard additionality test that, per requirements in the ACR Standard, must be re-assessed at minimum every 5 years. The methodology may become active again based on the results of the performance standard review.

Read more

The Methodology was developed by Safety-Kleen Kleen Performance Products. Lubricating oils are used to minimize friction and wear between mechanical parts in contact with each other and are essential to a wide variety of automotive, industrial, and marine applications. The lifecycle of lubricating oils is associated with environmental impacts including greenhouse gas emissions. The manufacture of lubricating oil is the most energy-intensive process in a crude oil refinery, and used lubricating oils are often burned in industrial or commercial boilers, releasing multiple pollutants including carbon dioxide.

An alternative option exists for used lubricating oil: collection and re-refining. Used oil management programs have been developed throughout North America in order to reduce the amount of improperly disposed used oil and to encourage the recycle and reuse of used oil. Lubricating oil must be taken out of service when it no longer performs to expected specifications. This occurs when additive packages become depleted and the lubricant becomes contaminated. The base oil portion of the lubricant, however, does not break down during use. As a result, used engine oil and other lubricating oils can be re-refined to remove water, contaminants and additives to produce base oil of the same quality as the virgin base oil. Lubricants formulated using re-refined base oils in turn can meet the same performance standards as those using virgin base stocks.

The purpose of the Methodology is to quantify greenhouse gas (GHG) emission reductions associated with the re-refining of used lubricating oils. Re-refining used lubricating oils avoids GHG emissions associated with the combustion of used oil at end of life. This Methodology provides the quantification and accounting frameworks, including eligibility and monitoring requirements, for the creation of carbon offset credits from the reductions in GHG emissions resulting from the re-refining of used lubricating oils.

INACTIVE: Methane Recovery in Animal Manure Management Systems

Previously, methodologies approved by the CDM Executive Board were approved for use on ACR for the registration of projects in non-Annex 1 countries or for registration of projects in the U.S. after ACR review and approval of special applicability conditions. Under ACR Standard v7.0, CDM methodologies are no longer accepted for crediting new projects on ACR. Therefore, ACR’s approval of the Clean Development Mechanism’s Small Scale Methodology: AMS-III.D Methane Recovery in Animal Manure Management Systems is withdrawn and the methodology is ineligible for crediting projects on ACR.

Read more

Methodology History

The methodology quantifies emission reductions associated with the introduction of anaerobic digestion technologies at a dairy farm. Biogas created through the digestion process can either be flared or beneficially reused to, for instance, produce electricity. Centralized digesters whereby manure is conveyed from a group of farms to a digester facility are eligible.

The methodology is applicable under the following conditions:

- Manure or the waste streams obtained after treatment are not discharged into natural water resources (e.g. river or estuaries);

- The annual average temperature at the project site is greater than 41°F;

- In the baseline scenario, the retention time of manure waste in the anaerobic treatment system is greater than one month, and if anaerobic lagoons are used in the baseline, their depths are at least 1 meter;

- No methane recovery and destruction by flaring or combustion for beneficial use takes place in the baseline scenario.

Finally, the methodology employs a performance standard for additionality whereby a project is deemed additional so long as there is no regulation impacting the project that requires the collection and destruction of methane from livestock manure.

INACTIVE: Grazing Land and Livestock Management

The ACR methodology for Grazing Land and Livestock Management (GLLM) is inactive and ineligible for crediting projects on ACR. ACR has determined that the methodology requires updates to measurement, monitoring, reporting and verification requirements to be consistent with the current version of the ACR Standard.

Read more

Methodology History

The methodology is applicable to beef and dairy production worldwide. It is designed to ensure the complete, consistent, transparent, accurate and conservative quantification of GHG emission reductions associated with a GLLM project. It focuses on five primary GHG sources, sinks and reservoirs (SSRs) affected by beef and dairy production – enteric methane, manure methane, nitrous oxide from fertilizer use, fossil fuel emissions, and biotic sequestration in above- and below-ground biomass and soils – and provides accounting modules for each of these.

The methodology’s modular structure gives livestock producers the flexibility to select the modules relevant to their baseline management and chosen GHG mitigation activity. To improve usability and cost effectiveness, the methodology provides a graduated approach to GHG accounting: a tool is provided for an up-front estimate of GHG impacts by SSR, using simple data inputs, and then the complexity and data requirements of the required GHG accounting methods correspond to the scale of impacts expected for that SSR. For micro- and small impacts, simplified accounting methods are provided.

The GLLM Methodology was developed by Winrock International with generous support from the David and Lucile Packard Foundation, and advice from a livestock Technical Advisory Committee.

GLLM Methodology lead authors:

- Tim Pearson, Winrock International – Ecosystem Services

- Nancy Harris, Winrock International – Ecosystem Services

- Nicholas Martin, Winrock International – American Carbon Registry

- Lauren Nichols, Winrock International – American Carbon Registry

- Jonathan Winsten, Winrock International – Environmental Resources Trust

- Jenn Holthaus, Winrock International – Environmental Resources Trust

- Gustavo Cruz, UC Davis / Cargill

GLLM Technical Advisory Committee:

- Shawn Archibeque, Colorado State

- Richard Conant, Colorado State

- Stephen De Gryze, Terra Global Capital

- David Diaz, The Climate Trust

- Alan Franzluebbers, USDA – Agricultural Research Service

- Karen Haugen Kozyra, Prasino Group / BIGGS project

- Ermias Kebreab, UC Davis

- April Leytem, USDA – Agricultural Research Service

- Arvin Mosier, USDA – Agricultural Research Service, ret’d

- Matt Sutton-Vermeulen, Prasino Group / BIGGS Project

- Juan Tricarico, Dairy Management Institute

INACTIVE: Southwestern Forest Restoration: Decreased Wildfire Severity and Forest Conversion

This methodology was never adopted for use by ACR. The expert Peer Review panel identified methodological issues that could not be rectified at the time, which prevented recommendation of adoption by ACR.

Read more

Methodology History

In 2015, the author team of Drs. Spencer Plumb and Katharine Woods (Sagebrush and Pine Consulting, Lab, LLC, and funded by the National Forest Foundation and its partners) submitted to ACR for consideration the carbon accounting methodology, “Southwestern Forest Restoration: Reduced Emissions from Decreased Wildfire Severity and Forest Conversion”. The methodology proposed a carbon accounting framework for the measurement, monitoring, reporting and verification of avoided GHG emissions from reduced risk of high severity fire through fuels reduction treatment and continued GHG sequestration by remaining forests, post-treatment.

ACR followed the process for development, review and adoption of new carbon offset accounting methodologies defined in the ACR Standard v.4.0 (Chapter 7). ACR completed internal review of the draft methodology in early 2016 and public comment was initiated during summer/autumn 2016. The complete public comment log, author team responses and the methodology draft resulting from public comment are available below. A panel of experts in the fields of forest fire science, forest management, forest carbon offset project development and verification, forestry carbon modeling and remote sensing was assembled with members from academia, government, NGO and private entities. The peer review panel began its initial review of the draft methodology in mid-2017. Although first of its kind and with many technical merits, ultimately, the review panel did not recommend adoption of the methodology by ACR, citing the concerns below among others:

- Insufficient parameter information to model fire and carbon stock

- Lack of accurate and conservative assessment of uncertainty

- Economic feasibility of projects and length of time before credits issued

- Frequency and magnitude of reversals and the impact to the buffer pool

- Additionality

- Consistency with ACR Standard 5.1 (now 6.0), ACR Improved Forest Management Methodology 1.3 and current Risk Mitigation Agreement and Buffer Pool Terms and Conditions

A summary of the review and the individual summaries of peer reviewers are available below.